Making best use of Efficiency: The Value of Genuine Komatsu Undercarriage Parts

Making best use of Efficiency: The Value of Genuine Komatsu Undercarriage Parts

Blog Article

Efficient Solutions: Undercarriage Parts for Heavy Equipment

When it concerns hefty equipment, the undercarriage is an essential part that commonly identifies the total performance and efficiency of the equipment. Quality undercarriage components play a considerable duty in guaranteeing the smooth operation and long life of hefty machinery. From excavators to dozers, each tool depends greatly on its undercarriage to hold up against difficult working conditions. Wear and tear are unavoidable, leading to potential problems that can impede productivity and rise upkeep prices. In this discussion, we will certainly check out the value of buying excellent undercarriage parts, usual wear difficulties dealt with by hefty equipment drivers, the benefits of prompt replacements, standards for selecting trustworthy providers, and essential maintenance ideas to expand the life-span of undercarriage components.

Relevance of Top Quality Undercarriage Components

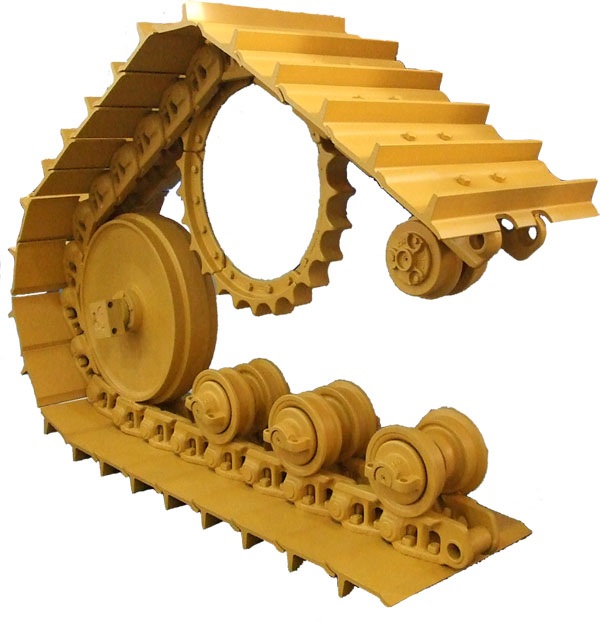

Quality undercarriage components are vital components in guaranteeing the sturdiness and efficiency of hefty equipment. The undercarriage of equipment such as excavators, excavators, and track loaders plays an essential function in sustaining the equipment's weight, offering stability on numerous terrains, and taking in the influence of unequal surfaces. By buying premium undercarriage components, drivers can substantially prolong the life-span of their machinery and lower the risk of unexpected malfunctions.

One secret advantage of utilizing high quality undercarriage components is the enhancement of total equipment performance. Durable tracks, idlers, sprockets, and rollers minimize friction and ensure smoother movement, inevitably bring about increased productivity and performance on task sites. Additionally, trustworthy undercarriage elements minimize downtime for maintenance and repair services, allowing drivers to maximize their functional hours and job due dates.

Typical Undercarriage Put On Problems

Advantages of Timely Substitute

One secret benefit of prompt undercarriage component replacement is raised device uptime. By changing worn parts before they fall short, the danger of unexpected breakdowns is lessened, minimizing downtime for repair services and maintenance. This aggressive approach not just maintains the heavy equipment functional yet also protects against prospective damages pop over here to various other parts that could result from a stopping working undercarriage.

In addition, replacing undercarriage parts quickly can enhance general efficiency. Spending in timely undercarriage component substitute is a positive strategy that pays off in terms of enhanced performance and lowered operational expenses.

Picking the Right Undercarriage Vendor

Choosing the appropriate undercarriage vendor is a critical decision that considerably affects the performance and maintenance of heavy equipment. When choosing a distributor for undercarriage parts, several variables should be thought about to ensure optimal performance and cost-effectiveness. A vendor that supplies a large choice of undercarriage parts for numerous hefty machinery brand names and models can be helpful as it supplies much more alternatives to meet certain requirements.

Stabilizing top quality, cost-effectiveness, and integrity is essential when choosing the ideal undercarriage vendor for heavy equipment. By meticulously evaluating these elements, you can pick a supplier that fulfills your requirements and adds to the effective efficiency and upkeep of your heavy equipment.

Upkeep Tips for Extended Life-span

To ensure a prolonged life-span for hefty equipment undercarriage components, carrying out a positive maintenance regimen is essential. Consistently examining undercarriage parts such as track chains, idlers, rollers, and gears for deterioration is critical. Any kind of indicators of damages or excessive wear must be promptly addressed to stop more damage and prospective failings. Additionally, keeping the undercarriage clean from dust, particles, and harsh products can considerably lengthen its life-span. Greasing relocating parts according to maker suggestions assists lower friction and avoid premature wear. Monitoring track stress and positioning is also essential to prevent uneven endure the undercarriage elements. Buying high quality undercarriage parts from respectable distributors is equally important for making certain long life. By following these maintenance tips vigilantly, heavy machinery owners can optimize the efficiency and longevity of their undercarriage parts, ultimately minimizing downtime and functional prices.

Verdict

In conclusion, high quality undercarriage parts helpful site are important for the reliable procedure of hefty machinery. Picking a dependable provider and following appropriate maintenance methods are essential to guaranteeing the extended lifespan of undercarriage components.

Too much wear and tear on undercarriage components of hefty machinery can lead to significant operational obstacles and increased upkeep prices. Routine examinations, proper upkeep, and prompt substitutes of worn undercarriage components are necessary to reduce these usual wear troubles and guarantee the ideal performance of hefty equipment.

A provider that uses a wide selection of undercarriage components for numerous hefty machinery brand names and designs can be helpful as it supplies more options to meet details demands.

By complying with these upkeep tips carefully, heavy equipment proprietors can optimize the performance and longevity of their undercarriage parts, ultimately minimizing downtime and operational costs.

Report this page